Project Details

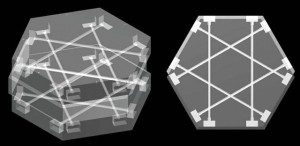

This project was a supply contract to the US Marine Corp to provide 3 precast concrete foundation systems to be used to support several 200 foot tall communication towers at various locations throughout the southwest US including, California and Arizona for the Land Mobile Enterprise Radio System. To resist high overturning loads, some towers are double layered and the weight of the foundation can exceed 1,000,000 lbs. The hexagon naturally occurs in nature and has been used throughout the past for its durability and functionality. Pre-Con has remodeled this fundamental shape to create a revolutionary foundation system suited for remote construction sites or locations where excavation is difficult. This unique design:- Is scalable in size, thickness and capacity.

- Is modular and can be disassembled and relocated.

- Can be assembled above or below ground.

- Can be considered as equipment under certain conditions.

- Can be quickly assembled for rapid deployment.

- Is capable of withstanding harsh environments.

- Does not require excavation.